Industrial Application – Containerised MBR System for Waste Water Treatment

Lootah Ready Mix Facility WWTP

S S Lootah Ready Mix Concrete LLC (SSLRM), established in 1989 and expanding with branches in Al Quoz and Jabel Ali. The Jabel Ali facility was direly in need of a Waste Water treatment as the client had very high tankering cost for moving of sewage from the labor camps (beside the facility) as well as increased fresh water requirement for the process. Further, the existing facility at Jabel Ali had limited space to collect and cater to the treat- ment of the produced wastewater, hence a requirement for a very compact, plug n play type system.

About the Project

The objective of the project was twofold:

- To treat the wastewater produced from the labor camps beside the ready mix facility and thus to minimize the tankering cost

- To eliminate the fresh water consumption for the processes within the ready mix facility by providing high quality TSE from the Waste Water Treatment plant for recycle / re-use

Scope & Realization

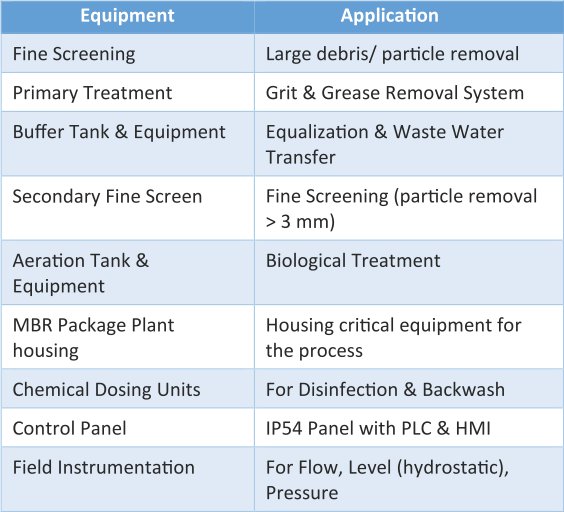

MENA-Water was awarded the contract for the complete design, construction, installation, testing, and commissioning of a water treatment plant within an impressive time-frame of just five months from the order placement. The primary objective of the project was to minimize site work and ensure a swift realization of the facility to avoid any disruptions to the existing operations.

In line with the project requirements, MENA-Water successfully constructed its innovative compact MBR package plant, specifically the MR300 U-version type. This compact plant was designed to meet the project’s objectives effectively. The proposed package plant excels in producing high-quality Treated Sewage Effluent (TSE) that precisely caters to the needs of ready mix processes, thus eliminating the requirement for fresh water at the site. This environmentally friendly solution not only reduces water consumption but also enhances the sustainability of the overall operation.

The compact MBR plant is expertly operated using a Programmable Logic Controller (PLC) and is continuously monitored remotely to ensure smooth and efficient operation. The advanced control system allows for real-time monitoring, prompt intervention, and optimal process control, ensuring consistent and reliable performance. As scheduled, the plant was successfully built and put into operation within the agreed-upon time-frame.

System Benefit

- Reduced sewage tankering cost

- Full automatic system operation with Online moni- toring facility

- Adaptable to future demand due to modular system Well-proven, complete and clean system solution

- Recycling wastewater in processes within the ready mix facility

Technology and Advantages

- Membrane Bioreactor (MBR) – Package Plant

- High permeate quality via Ultrafiltration suitable for re-use

- Higher MLSS concentration Less sludge with better quality Smaller footprint & Less Odour Minimum works for site installation and civil structures