Hassyan Power Plant WWTP, Dubai, UAE

China Harbour Engineering Company

China Harbour Engineering Company Ltd (CHEC) established in 1980 is an engineering contractor and a subsidiary of China Communications Construction Company (CCCC), providing infrastructure construction, such as marine engineering, dredging and reclamation, road and bridge, railways, airports and plant construction.

Hassyan Power Plant WWTP

The 2,400MW Hassyan clean coal power station is an ultra-supercritical (USC) power plant project being developed in Saih Shuaib, Dubai, United Arab Emirates (UAE). The plant was originally designed to operate on coal but subsequently, based on a decision by DEWA, the offtaker, with the blessing of the Chairman of the Dubai Supreme Council of Energy on 2nd February 2022, it was switched to operate on natural gas. The decision to operate with gas instead of coal aligns the Dubai Clean Energy Strategy 2050 and Dubai’s carbon neutrality strategy by 2050 to provide 100% of the energy production capacity from clean energy sources by 2050 while ensuring Dubai’s energy supply security by maintaining a diversified energy mix. With operation on natural gas instead of coal, the project will thus avoid approximately 30 million tons of CO2 emissions just by 2030.

Construction of the $3.4bn power plant commenced in November 2016. The objective of this project was to treat wastewater from the administration facility at the power plant site as well as from the ships discharge periodically. The inlet wastewater as a result could sometimes be with variable loads and hence the need for a robust technology to handle increased loads. The treated water was planned to be re-used within the existing facility for Landscaping & Irrigation purposes.

Scope and Realization

In December 2018, MENA-Water was awarded the contract for the complete design, construction, installation, testing, and commissioning of the Waste Water Treatment plant. The primary objective was to ensure minimal site work and a quick realization of the facility to avoid disruptions to the existing operations.

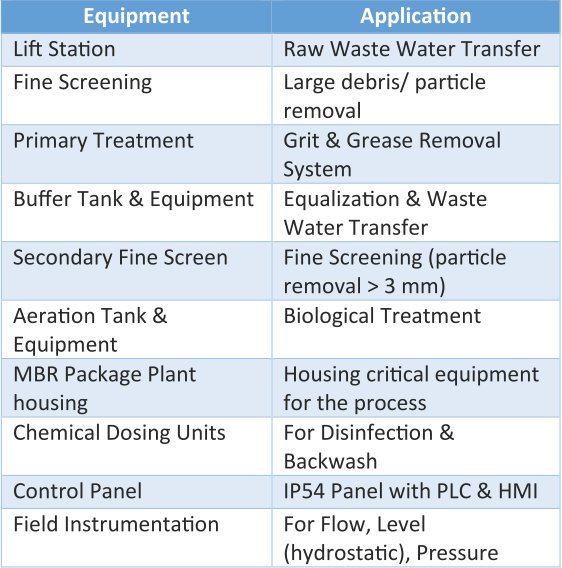

To fulfill the project’s goals, MENA-Water implemented its innovative compact MBR package plant, specifically the MR75 U-version type. This advanced system was chosen to meet the specific requirements of the project. The effluent produced by the membrane plant consistently achieves the highest quality standards, with total nitrogen levels consistently below 10mg/l, and BOD and solids levels below 5mg/l.

To ensure efficient and reliable operation, the compact MBR plant is equipped with a Programmable Logic Controller (PLC) and remote monitoring capabilities. This allows for real-time monitoring, prompt troubleshooting, and optimal control of the treatment processes.

After successful installation and rigorous testing, the Waste Water Treatment plant was handed over to the client in August 2019. The completion of the project within the specified timeline demonstrates MENA-Water’s commitment to delivering high-quality solutions while minimizing disruptions to the existing facility’s operations.

System Benefit

- Full automatic system operation with Online monitoring facility minimal site work and quick realization

- Recycling wastewater in within the plant for landscaping

Technology and Advantages

- High quality effluent suitable for irrigation purposes and/or reuse as process water.

- Higher MLSS concentration less sludge with better quality smaller footprint & less odour

- Minimum works for site installation and civil structures