Mechanical or Primary Treatment is the first and basic important stage of the water treatment process.

The purpose of this treatment is to remove most of the non-soluble solids physically in order to reduce the pollutant loads and to protect all the subsequent steps in the treatment plant.

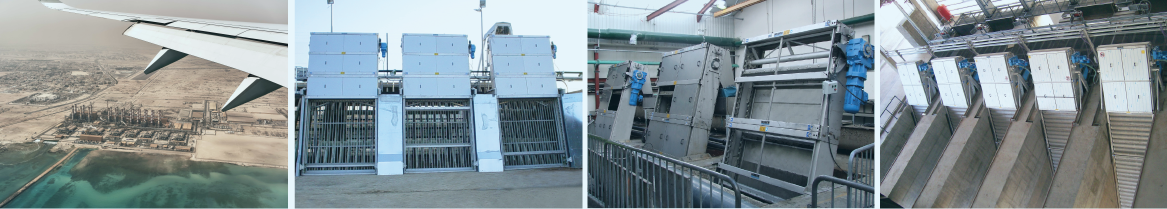

Providing a reliable, high-quality supply of treated water is critical to many processes. However, selecting the right Pre-Treatment technologies is very essential in the field of water treatment.

It requires a comprehensive evaluation of the raw water quality and process requirements, the system design, operating conditions, and economics. We MENA-Water have the experience and expertise to specify the right pre treatment system for standard applications and custom design systems to meet specialized needs.

Mechanical Pre-Treatment incorporates the following processes:

- Screening step which aims for removal of solids

- Washing compactor cleans/compact fibrous materials from the screen for easy handling

- Grit removal step aimed for settling of all sand with larger in size than 0.15 mm

- Sand classifier and sand washer are used to wash the sand and dry it for reuse

- Grease & oil removal by floating to the surface by air and thereby skimming off

Equipment Information

- Mechanical TreatmentMechanical or Primary Treatment is the first and basic important stage of the water …

- Drum ScreenDrum screens are ideal for wastewater pretreatment in small and medium-sized sewage treatment plants …

- Ultra Fine ScreensUltra-fine screens for new applications.

- Multi Rake ScreenMulti Rake Bar Screen for mechanical pre-treatment.

- Perforated Belt ScreenThe waste water flows through perforated filter elements made of stainless steel.

- Grab ScreenThe waste water flows through a grating screen made of steel or stainless steel,

- Climber ScreenVery robust screen for channels.

- Step ScreenStep Screens are a ”stepping” type of screening systems for separating suspended solids.

- Inclined Drum ScreenScrew screen compactor with reinforced shaftless spiral for channels.

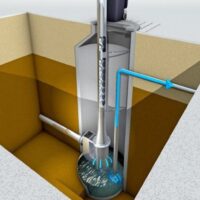

- Vertical Screw ScreenThis screw-screen-press-system is suitable for vertical installation as combined machine.

- Basket ScreenThe basket screen is excellent for installation in pumping stations and manholes.

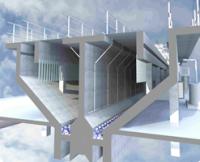

- Storm Water Screen – Horizontal ScreenThis is a belt screen or screw screen of horizontal design.

- Washing CompactorWaste disposal is a cost factor for each installation.

- Micro Filter ScreenThe Micro Filter Screen can relieve primary treatment burden

- Grit WasherThe grit washer unit consists of two basic items – grit wash tank and …

- Grit ClassifierGrit classifier are used for the separation of solids from water and consisting of …

- Circular Grit Trap – VortexThe Vortex Grit Trap is used to screen and wash sand present in water.

- Longitudinal Grit TrapA high performance and low operating cost equipment.

- Package Inlet WorkThe complete preliminary treatment of waste water in one compact plant includes

- Screw ConveyorScrew conveyors are used to convey sludge or solid matter like grit or screenings.

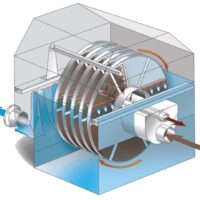

- Containerized Disc Filter RoDisc®RoDisc® Package Solutions for removal of micropollutants. The HUBER Disc Filter RoDisc® is a …