Industrial Wastewater Treatment

Construction of Four Slaughter House and Ancillary Buildings at Al Salamat, Ain Al Fayda, Al Quaa and Masaken, Al Ain – UAE

Treating wastewater from food industries is challenging due to the high levels of BOD₅, COD and fat. Specialized equipment like Dissolved Air Flotation (DAF) is needed to reduce the levels of pollutants before biological treatment. This consists of a Membrane Bio-Reactor (MBR) system

that further breaks down the effluents to reach the designated parameters for disposal or reuse.

Slaughtering & Processing Water Treatment

Plant Capacity 4x 75m³/d

In April 2016 MENA-Water accepted this challenge for four sites in the town Al Ain with plants for treating slaughter house wastewater from processing, packaging, equipment cleaning and disinfection with a MENA-Water system for 75m³/d for each plant.

Scope and Realization

The complete turnkey design with construction and commissioning was done within 6 months and the four plants were successfully put into operation as scheduled. Additionally site visits, maintenance and monitoring for the first year of operation was part of the contract.

The complete turnkey design with construction and commissioning was done within 6 months and the four plants were successfully put into operation as scheduled. Additionally site visits, maintenance and monitoring for the first year of operation was part of the contract.

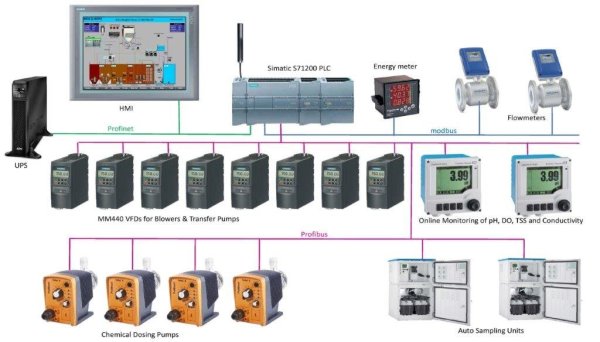

All equipment was supplied from approved vendors and complies with strict specifications from the Abu Dhabi Sewerage Services Company. The limited space constraints required an installation of all this equipment within smallest area of less than 100m². The whole plant is auto controlled using the total integrated Siemens Automation Platform. All field devices are connected to the PLC using fieldbus protocols to increase the deeper engagement of automatic controls for finer process tuning. Each of the facilities is remotely monitored by the Municipality Maintenance Management System (CMMS) using GRPS modems installed at each PLC and giving SMS alarms to operators.

The whole plant is auto controlled using the total integrated Siemens Automation Platform. All field devices are connected to the PLC using fieldbus protocols to increase the deeper engagement of automatic controls for finer process tuning. Each of the facilities is remotely monitored by the Municipality Maintenance Management System (CMMS) using GRPS modems installed at each PLC and giving SMS alarms to operators. more Information

more Information

at Download

| Equipment | Application |

| Basket Screen | Coarse Particle Removal |

| Lifting Station | Effluent Transfer |

| Micro Fine Screen | Particle Removal > 1mm |

| Dosing System | NaOH, Ferric Chloride, Polymer |

| Pipe Flocculation | Chemical Addition |

| Dissolved Air Flotation | COD & TSS Removal |

| Aeration Tank No. 1 & 2 | Biological Treatment |

| MBR Modules | Ultra-Filtration |

| Activated Carbon Filter | Odour Control System |

| Dry Bag System | Sludge Dewatering |

| Field Instruments | For Flow, Level (hydrostatic), TSS, DO, Pressure |

| Form 2 Control Panels with PLC | Total Integrated Automation Platform with Profibus |

| Central SCADA linking to CMMS system | Monitoring of all Process Values in Headquarter |