SBR Sewage Treatment Plant with Tankerstation

HAG YUSIF STP, KHARTOUM NORTH – Sudan –

Municipal and Industrial Sewage:

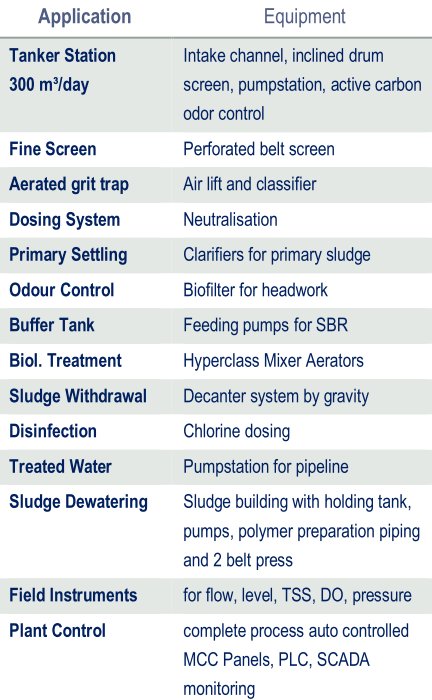

MENA-Water renewed and increased the sewage treatment plant in Hag Yusif in Khartoum, Sudan. At the same time a conversion to SBR process and the installation of a tanker station took place. The SBR treatment plant capacity is 17000 m³/d. The updated headwork can handle 40 000 m³/d.

Initial Situation

The sewage of the industrial zone at Khartoum North was pumped out of the town and stored in open lagoons. There was an old treatment plant of 1965 with pretreatment, sludge digesters and biological treatment in ponds which is fully bypassed since decades causing bad odour and danger of overfow.

MENA-Water signed the APC contract to rehabilitate the complete plant with transfer to SBR system, suitable for heavy organic load and effluent water usable for irrigation.

Plant Update

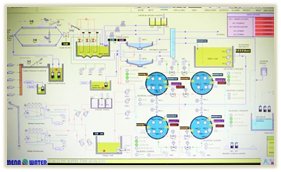

The existing civil structure was reused, rehabilitated and completed with new buildings. All technical equipment was renewed including automatic PLC control with SCADA monitoring.

Headwork

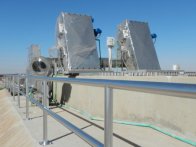

The Headwork consists of 3 screening channels for two automatic perforated belt screens and one bypass protected by manual bar screen, followed by aerated grit trap and 2 primary clarifiers. The excess odour will be treated by biofilter.

All sewage flow will be by gravity up to buffer tank. There are place 3 submersible feeding pumps for alternating fill of the 4 SBR tanks.

SBR Process

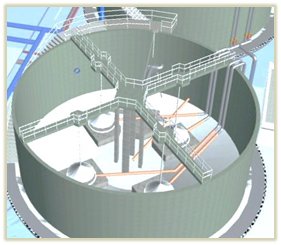

The Sequence Batch Reactor is using an intermittant process of filling, treatment and emptying with flexibility to match different organic load. It is best suited for industrial wastewater.

This plant is operating with 4 tanks and each 4 hyperclass mixer-aerators. Air blower stations are supplying compressed air for oxigenation to support the activated sludge process.

All process control will be with PLC system and flexible selection of the treatment cycles. SCADA system will allow tele monitoring from control center and remotely supervision.

Sludge Dewatering

The excess sludge is removed by gravity to sludge holding tank and here mixed with the primary sludge. Treatment will be by 2 belt press in sludge deatering building with pumping, polymer preparation, mixing and full automatic control. Dewatered sludge will achieve 20% TS and can be dried at sludge storing area.

In emergency the excess sludge can be storaged at sludge lagoon.

Effluent Pumping Station

Treated water from the SBR tanks, after disinfection, flows by gravity to the pumpstation or in case of emergency to the hazard storing lagoon.

In any case of shut off diesel generators will allow to run selected equipment whilest the SBR-process will set hold status for immediately continue after power return. In any case of partial malfunction there are many bypass posibilities for continue the treatment process.

Desert Greenery

The treated water is pumped with 27 km pressure pipe line to holding ponds outside the town and helps with irrigation of the greenery.

Plant Video

more Information

more Information