Cost-effective sludge dewatering for independence in sludge disposal

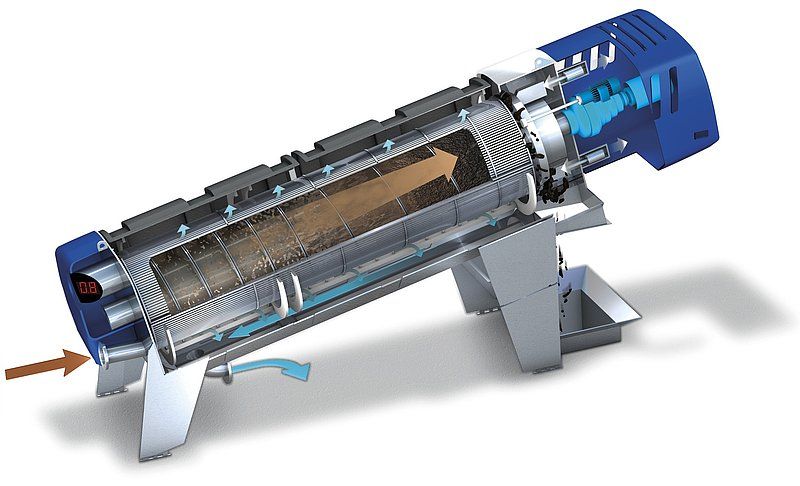

The Q-PRESS® is a screw press with a conical screw shaft and cylindrical sieves consisting of three treatment zones: inlet and drive zone, three-part thickening and dewatering zone, and press zone with pneumatic counter-pressure cone.

In the first part of the thickening and dewatering zone the supernatant is quickly removed by the feed pump via a large free filter surface at a low primary pressure.

technical information

at www.huber.de

A pressure probe in the feed area controls the primary pressure thus ensuring a constantly high filtrate quality.

In the second part of the screen the volume of material between the screw flights is reduced by the conical screw and the sludge pressed against the inner screen surface so that the sludge is dewatered, with a continuous reduction of the filter cake thickness. The screen apertures are much smaller in this screen section.

In the third part of the screen the residual water is pressed out of the sludge, at a minimum filter cake thickness, by the pneumatic counterpressure cone at the press discharge. The dewatered sludge is pushed by the conveying screw past the pressure cone into the discharge chamber. The sludge residence time in the screw press and thus the filtration time can be adjusted to individual requirements by adjusting the rotational speed of the screw shaft.

In the third part of the screen the residual water is pressed out of the sludge, at a minimum filter cake thickness, by the pneumatic counterpressure cone at the press discharge. The dewatered sludge is pushed by the conveying screw past the pressure cone into the discharge chamber. The sludge residence time in the screw press and thus the filtration time can be adjusted to individual requirements by adjusting the rotational speed of the screw shaft.

This equipment is available in a containerized and mobile version for quick realization and full operation flexibility.

Please find reference with Mobile Q-Press.

Please find more information about Containerized Sludge Dewatering.