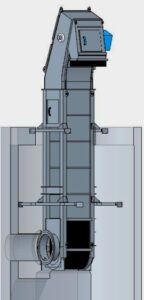

Multi Rake Bar Screen for mechanical pre-treatment.

Parallel to the increasing demands of users, we introduced modifications to the basic design. These have resulted in an optimum product for the preliminary treatment of waste water-providing high performance coupled with low operating costs.

Function:

The waste water flows through bars made of stainless steel, while contaminants are held back. Solid matter is picked up directly at the bottom of the channel without the need for a base step.

The cleaning elements are fixed between two chains and are designed with teeth for the best cleaning of the screen. The screenings can be discharged into containers, wash compactors, screw conveyors, conveyor belts etc. Sealing at the sides prevents solids from circumventing the filter. As an option we can deliver a flexible rake.

Features:

- High reliability through robust construction – no need for upstream coarse screening.

- The Multi Rake Bar Screen allows the passage of grit without malfunctioning.

- Slot opening starting from 2mm

- Discharge of grease in large quantities presents no problem.

- Filter elements optimally cleaned as result of their teeth.

- Screenings conveyed positively to the discharge point.

- Excellent cost/performance ratio

- Low maintenance costs

- Suitable for outdoor sites / operation in winter

- Easily adapted to suit changed operating conditions

- Machine completely hygienically encapsulated

HUBER Multi-Rake Bar Screen RakeMax® CF PS –

the centre flow version for pumping stations and

manholes

- The innovative variant of the well-proven HUBER Multi-Rake Bar Screen RakeMax®.

- The PS version is connected directly to the sewer pipe in the manhole structure via a flange connection.

- Increased separation efficiency due to flow deflection in the bar rack in a very confined space.

- Integrated emergency overflow.

- Robust and powerful machine for the removal of debris and other solids.

- Optimal hydraulic utilisation of existing channels.

Applications in municipal and industrial clarification plant:

- waste water pre-treatment / fine screening

- sludge screening / secondary sludge

- sludge screening / primary sludge

- sea water treatment

- rainwater tank overflow and storage channel screening

- fecal matter reception and treatment

Applications in the paper and cellulose industry:

- wash water, unbarking installations

- coarse matter runoff, channel water

Applications in power stations:

- cooling and service water screening (river intake etc.)

- sea water screening

Industrial applications:

- cooling and waste water screening (river intake etc.)

- sea water screening

- textile and textile finishing industry – preliminary clarification of total waste water

- meat, fish and poultry processing / slaughter-houses – preliminary clarification of total waste water

- sugar industry – preliminary clarification of total waste water

- composting installations, waste product and disposal engineering, seepage water treatment

- fruit and vegetable processing – preliminary clarification of total waste water

- breweries – preliminary clarification of total waste water

- animal meal production– preliminary clarification of total waste water

- removal of algae

Find more information at: www.huber.de