Mobile Treatment Plants for Sludge Dewatering – Reduce your Sludge

MENA-Water is manufacturer of containerized plants for sludge handling. For every case of application, we offer a solution ready to use: mobile or stationary.

MENA-Water is manufacturer of containerized plants for sludge handling. For every case of application, we offer a solution ready to use: mobile or stationary.

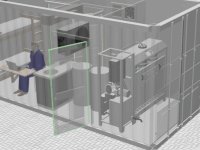

All process equipment is arranged inside one 40feet or 20feet standard container. This enables us to achieve very short realization time. You will get reliable and tested plants and only need plug and play at site.

The selection of the sludge dewatering technology depends on the capacity and the operation recommendations. Therefore we use different machines to exactly match the conditions at site. This starts with small Dry Bag plants and varies from Belt Press for medium, Screw Press for higher and the Centifuge for highest capacity.

The selection of the sludge dewatering technology depends on the capacity and the operation recommendations. Therefore we use different machines to exactly match the conditions at site. This starts with small Dry Bag plants and varies from Belt Press for medium, Screw Press for higher and the Centifuge for highest capacity.

FEATURES

- Fast delivery and start-up due to the mobile concept

- Quality equipment in stainless steel

- Compact design

- High packing density

- Very good price-performance ratio

- Low maintenance and minimum operation requirements

- Minimum construction work on site and easy to relocate

Belt Press

A very reliable technology for medium capacity is the belt press with pre-thickener completed with polymer preparation, mixer, tanks, pumps included cabling and piping. Everything will be pre-installed.

Sludge is pumped, stored and polymer is prepared, dosed and mixed to the sludge flow towards the dewatering machine. Upstream there is the screw pre-thickener which performs the initial solid/liquid separation stage, taking sludge solids concentration from 0.5 -3% up to 5-15 %. The dewatering in the following belt press occurs firstly in the low pressure zone, then in the wedge zone and finally in the high pressure zone where the filter cake is compressed between the perforated cylinder cloth and the main cloth. The discharged sludge cake can reach dry solid contents variable from of 18 to 30% depending on the sludge.

MENA-Water offers tailor-made containers to treat sludge from different applications:

- Municipal sludge

- Industrial sludge

- for mixed fiber, biological, chemical sludge

- The belt press will handle sludge flow from 2 to 8 m³/hour per single unit

- The dry cake will be 18-30% DS due to type of sludge

- High capacities can be achieved through modular arrangement

SCREW PRESS

The Q-PRESS is a very reliable equipment, containing all process for sludge dewatering inside one machine. Installations can easily achieve a sludge volume reduction in excess of 90% with simple operation and low maintenance at minimum energy consumption. Furthermore, direct dewatering of the thin sludge avoids all additional costs that would incur for the operation of an upstream mechanical thickening system. If it comes to amortisation and clean and easy operation, the screw press will be the favourite selection. Please find Reference Report.

This plug&play containerized solution is available from 2 – 30 m³/h activated sludge dewatering.

Please find more Info to Q-Press.

DRY BAG

For small applications we offer this system using drying bags. The very small footprint of the plant allows best placement.

The package plant is completely automatic, with all functions, including sludge conditioning, bag filling and draining cycles, controlled by an integral control panel. The automatic filled bags also act as strong containers for transport of the dehydrated sludge to the disposal point.

CENTRIFUGE

Movie of Containerized Belt Press

MENA-Water Containerized Plants

SLUDGE PUMPS

Sludge pumps can handle nearly every media from liquid to slow moving media, up to materials including solids.

more Information

more Information