Fracking water as a produced water generated during production of crude oil is highly contaminated with heavy metals, toxins and hydrocarbons. Therefore this produced water is difficult to treat and stored in big lagoons causing environmental problems. MENA-Water took the challenge and developed a process involving multiple treatment steps eliminating the pollutants to the permissible discharge into marine water.

The plant is based on electrocoagulation, chemical oxidation and UV oxidation to break the compounds in form that can be easily removed in physical, biological and chemical processes.

Electrocoagulation is considered as high effective in fracking water treatment due to the high salinity which results in high conductivity.

The plant contains several treatment steps:

- Chemical neutralization and coagulation

- Free oil separator / Precipitator

- Electrocoagulation

- Secondary coagulation / flocculation

- Dissolved Air Flotation

- Biological striping and clarification

- Multiple filtration processes

- Advanced UV Oxidation

- Ultrafiltration

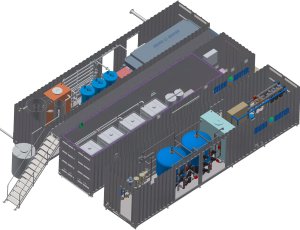

Along the philosophy of MENA-Water all equipment is arranged inside containers to achieve the well known flexibility and short realization time.

Further on there are lots of avantages:

- Modular compact package system in containers for mobility

- Sturdy construction, corrosion resistant components

- Effective removal of Pollutants such as Algae, COD, Iron, barium, silica and bakteria

- Safe discharge to marine courses

- Very low waste (<3%), from backwash

- Cost effective and fast delivery

- Auto control and online monitoring for parameters

Please find more information for a package plant with 250 m³/day.